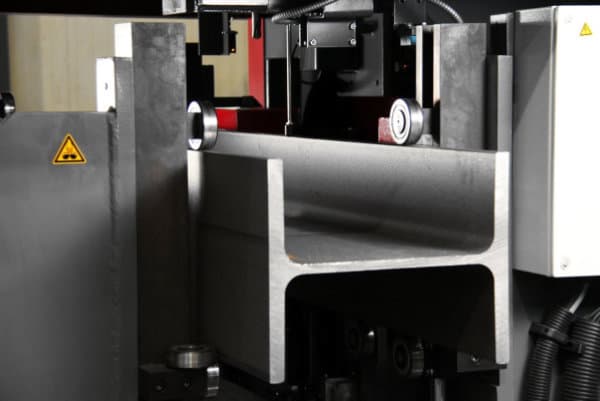

MultMaster acts as an extension for the Roller Feed measurement device to perform cuts that otherwise would require manual positioning. This accessory allows for fast material processing using a Voortman drilling and saw tandem system.

Programming the CNC Beam Drill Line program is simple even if done manually. Peddimat software is used to program the CNC Beam Drill Line. Most operators can learn how most parts are programmed in under an hour. Of course practice makes perfect. However, it is easiest to program the machine from a CAD file. It is recommended that you use a 3D modeling software, such as StruMis or ProSteel 3D to create the CAD drawings. These files can then be imported directly into a machine. The operator just needs to select the part that is to be processed, and hit the Cycle start button.